Service hotline

+86 18518316054

Current location : Home page > Products > In situ infrared system > High Voltage In-Situ Infrared Spectroscopy Measurement System (HP ATR FT-Mir)

Current location : Home page > Products > In situ infrared system > High Voltage In-Situ Infrared Spectroscopy Measurement System (HP ATR FT-Mir)

Model:CEL-HPATR4000

Place of Origin:Beijing

System application:

The CEL-HPATR4000 High Pressure In-situ Infrared Spectroscopy Measurement System (HPATR FT-Mir) can be used for on-line monitoring of high pressure/supercritical (SCF) systems induced by the microscopic dynamic processes of physical transformation or chemical reactions under real experimental conditions, in a wide range of pressure and temperature, and under sufficient stirring. The instrument can be 0.1 ~ 40 MPa, 20 ~ 200 ℃, and under the magnetic force stirring of 0 ~ 1000 RPM stable work, detect the phase behavior of high pressure/supercritical system and the interaction between components, monitoring of active species along with the development of pressure, temperature, time and so on, studies the kinetics and mechanism of micro dynamic change process.

Background note:

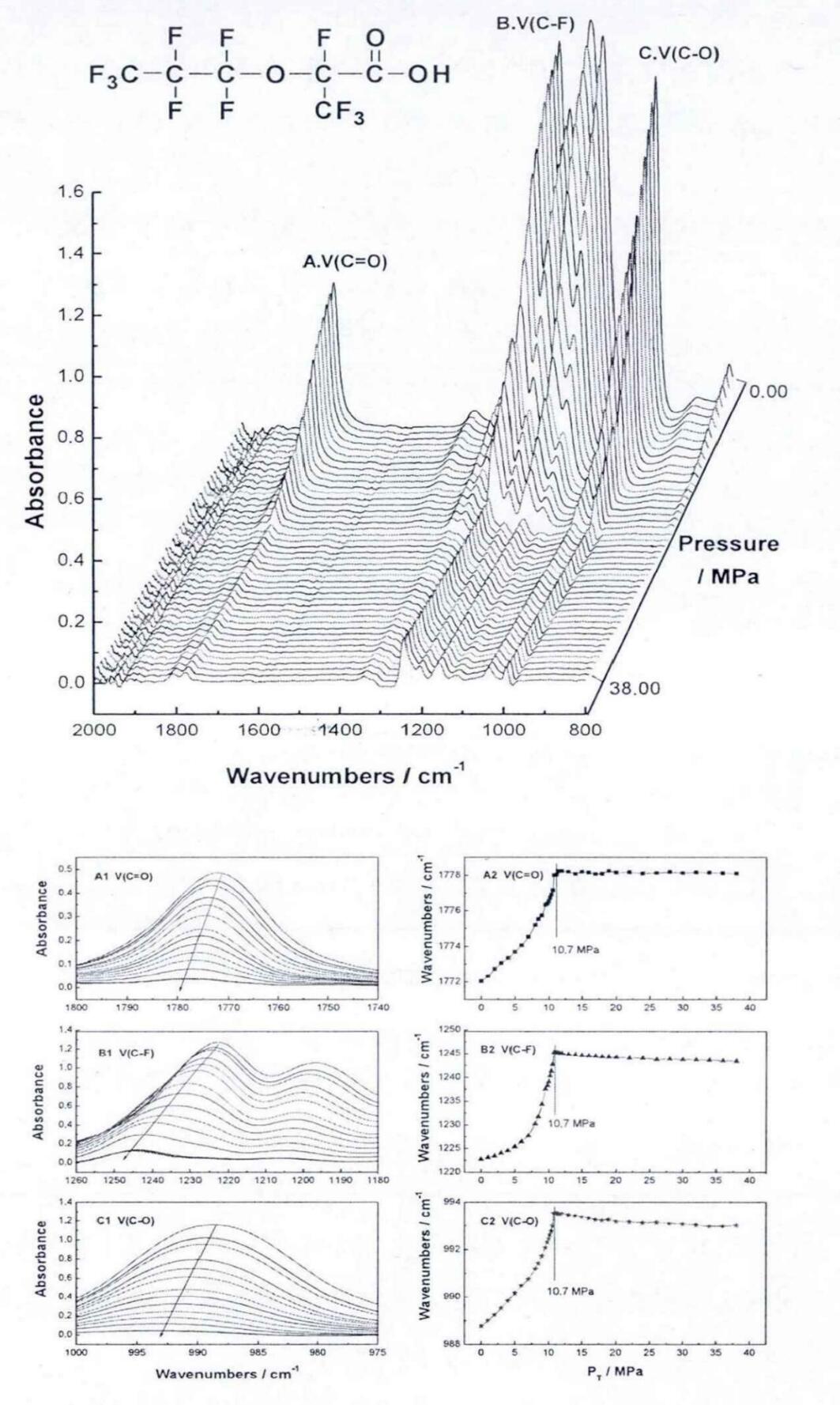

Organic functional groups with the characteristics of the infrared spectrum summit within the molecule or molecules and extremely subtle changes in the interaction of high pressure in situ ftir can be real-time monitoring system of supercritical carbon dioxide (scCO2) physical process or chemical reaction in the process of the change of infrared absorption spectra, dynamic indicates the corresponding two component system developing process of interaction between the molecules, This is helpful to explore the microscopic mechanism of solvation of dispersions in gaseous phase and SCCO2, and reveal the nature of CO2-philic substances easily soluble in SCCO2.

High pressure in situ spectroscopy is a high pressure experimental technique that can be used to monitor the physical transformation or chemical reaction process in a supercritical system. The phase behavior of Supercritical Fluids (SCF, Supercritical Fluids, carbon dioxide, water, ammonia, ethane, ethylene, pentane, etc.) and the interaction between each component were detected in real time, and the influence mechanism of temperature and pressure on the system was explored. This technology plays an important role in understanding the changing law of SCF system, regulating the reaction process and promoting the application of SCF technology.

Infrared spectroscopy (IR) is the molecular absorption spectrum of selective absorption of infrared radiation and vibrational energy level transition. Moreover, infrared spectroscopy has the advantages of strong characteristic, fast scanning speed, simple operation and can analyze samples in various states, which is an effective method for group analysis, molecular structure characterization and compound identification. Due to the above characteristics of IR spectrum, the molecular structure information presented by IR spectrum can be used to clearly analyze the chemical reaction process and the interaction between components. Especially under different reaction conditions such as temperature and pressure, the interaction between molecules in the system will inevitably change the electron distribution of the interacting molecules, resulting in a slight change in the bond length and polarity of some chemical bonds inside the molecules. Changes in bond length, polarity and strength will also cause sensitive changes in vibration absorption frequency and/or intensity of related covalent bonds in solute, and it can be monitored sensitively in real time by using infrared spectroscopy technology, and the chemical reaction process and the interaction mechanism of each component can be explained by molecular vibration. This is of great significance for understanding the essence of chemical reaction.

FT-IR is very sensitive to polar covalent bonds, so FT-IR becomes an effective technical means to explore the molecular interaction of dispersion-SCCO2 system. HP ATR FI-IR can measure high concentration samples and real-time monitor the changes of infrared absorption spectrum during the physical and chemical changes in SCCO2 system. Therefore, Hp ATR FI-IR is considered to be an effective method to study the solvation and chemical reaction process of SCCO2 system. Therefore, the high-pressure in-situ mid-infrared spectroscopy online monitoring device (Hp-ATR FT-MIR) designed and developed by our company can real-time monitor the phase behavior and solvation process of the two-component system composed of SCCO2 and dispersions under different pressure or temperature conditions.

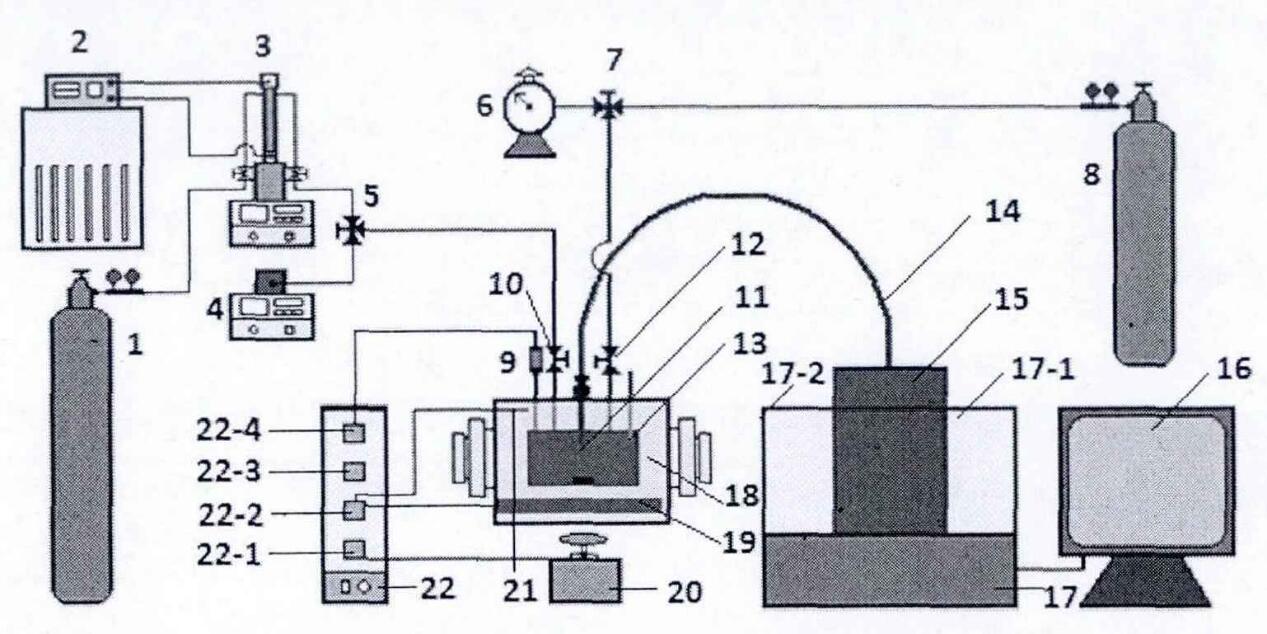

Carbon dioxide cylinder, 2. Cooling pump, 3. High pressure injection pump, 4. Metering pump, 5. Gas liquid three way valve, 6. Vacuum pump, 7. Nitrogen three way valve, 8. Nitrogen bottle, 9. Pressure sensor, 10. Intake valve, 11.ATR infrared sensor, 12. Exgress valve, 13. Temperature measuring thermocouple, 14.IR optical fiber, 15. Reflection chamber, 16. Computer, 17.FT-IR infrared spectrometer, 18. High pressure reaction kettle (infrared sample tank), 19. Heater, 20. Magnetic Stirring, 21. Thermocouple for Temperature Control, 22. Controllers, 22-1. Electromagnetic Trimmer Governor, 22-2. Temperature Controller, 22-3. Temperature Display, 22-4. Pressure indicator

Technical advantages:

The CEL-HPATR4000 high pressure in-situ infrared spectroscopy test system (HPATR FT-Mir) uses a relatively independent infrared sensor set inside the high pressure reactor to strip the attenuated total reflection crystal of the infrared light sensing element from the pressurized shell at the bottom of the high pressure sample tank. The infrared sensor adopts crystal material with good pressure resistance, medium infrared light transmission performance and high refractive index as the damping total reflection prism. The volume of the damping total reflection prism and the bearing section area of the infrared sensor are reduced, and the pressure resistance of the system is improved. The reflection chamber, optical fiber and infrared sensor are used to set the analysis light path, and the mid-infrared light emitted by the infrared emitting device of the infrared spectrometer is transmitted to the detection plane of the infrared sensor through the reflection chamber and optical fiber to realize the effective coupling with the samples to be tested inside the high-pressure reactor. The analysis light path through the infrared sensor is relatively independent and not affected by the position deviation of the high pressure reactor, etc., which overcomes the disadvantages of the existing attenuation-total reflection high pressure in-situ infrared monitoring device, such as complex structure, tedious light path calibration and inaccurate detection. The electromagnetic stirrer is set under the high pressure reaction kettle (high pressure infrared sample tank) to stir the test samples during the monitoring process, which improves the mass transfer and diffusion rate and test efficiency, improves the mixing uniformity of each component in the sample to be tested, and improves the representativeness and reproducibility of the online spectral test results. The CEL-HPATR4000 high pressure in-situ infrared spectroscopy measurement system (HPATR FT-Mir) has the advantages of reasonable design, convenient use and accurate monitoring, and can be used for on-line monitoring of physical transformation and chemical reaction processes under high pressure and supercritical conditions.

Technical parameters:

specifications | parameter |

Infrared high pressure sample tank (reaction kettle) | 50ml, standard 316L stainless steel (optional Hastelloy alloy) |

The sample pool | Sapphire window 2 |

Apply to system | Supercritical system, high pressure system, homogeneous reaction system |

Applicable spectral range | 4000~500cm-1 |

Magnetic stirring | <1500rpm |

pressure | <40Mpa |

temperature | <200℃ (473K), PID control, programmed temperature rise |

Optical fiber | Double-headed light guide fiber, 1 set of infrared sensor |

The valve pipe | Swagelok, 1/16inch |

High pressure liquid feed pump | American SSI Series Ⅱ |

optional | FT-IR Infrared Spectrometer (PE, Shimadzu, Brooke, thermoelectric, etc.) |